Industrial Boilers

Leading Manufacturers, Exporters and Wholesaler of Atmospheric Fluidized Bed Boiler, Boost Pac Water Cum Smoke Tube Boiler, IBR Steam Boiler, Super Pac Water Cum Smoke Tube Boiler, Water Tube Boiler and Wood Fired Boiler from Karnal.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Atmospheric |

| Warranty | 1 Year |

| Shape | Rectangular |

| Brand Name | CBPL |

| Material | Stainless Steel |

| Certification | ISI Certified |

| Voltage | 380V |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Automatic |

| Warranty | 1 Year |

| Brand Name | CBPL |

| Material | Stainless Steel |

| Fuel | Coal, Bagasse, Wood Logs / Wood Chips, Saw Dust, Biomass Fuels |

| Capacity | 1 TPH to 12 TPH (F&A 100OC) |

| Pressure | 10.54 Kg/Cm2 (g) to 21 Kg/Cm2 (g) |

Preferred Buyer From

| Location | Anywhere in India |

The BOOST PAC Boiler with its high performance and automatic modern styling confirms to the most exacting standards of safety, performance and efficiency. This boiler is manufactured with the latest engineering techniques, modern production equipment and with the expertise engineers and workers. The benefits include fuel flexibility, high efficiency, low emissions and reduced capital and operating expenses.

Boost Pac is a two-pass, smoke tube boiler that can be fired on wood and optionally Coal, Bagasse etc. The boiler has a unique design membrane water wall type boiler which combines the advantages of water tube & smoke tube designs . The front end and shell rear end is closed with the help of tube sheets. The flue tubes are fitted between the front and rear tube sheet. The flue tube opens into the smoke Box. The pressure part consists of shell, tube sheets, valves & fittings, (level gauge, Mowbray) feed water piping etc. The rear door when opened, gives total access to the Smoketubes.The cylindrical boiler shell is fully covered with glass wool insulation and enclosed in a sheet at site. Steam is collected through the steam outlet. Man Hole is given for cleaning purpose.

Features :

- Offer improved efficiency in the most economical manner

- Substantial Savings on fuel costs

- Fixed grate, dumping grate & burner with Multi-fuel firing as per requirment.

- Optimum combustion with appropriate spreader attached with fuel Feeder

- Manual & Automatic Fuel Feeding Facility

- Machine-welded membrane panel

- Membrane panels provide gas tight enclosure for better efficiency of boiler & minimum refractory

- Dependable quality of components like valves, pumps, safeties & instruments

- Easy access for cleaning and inspection

| Business Type | Manufacturer, Exporter, Supplier |

| Type | IBR |

| Material | Cast Iron, Stainless Steel |

| Certification | CE Certified |

| Application | Industrial |

| Voltage | 380V |

| Capacity | 1000-25000 kh/hr |

| Driven Type | Electric |

| Warranty | 1 Year |

| Brand Name | CBPL |

Preferred Buyer From

| Location | Anywhere in India |

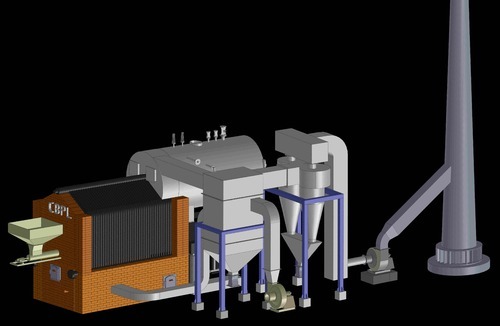

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Automatic |

| Warranty | 1 Year |

| Brand Name | CBPL |

| Fuel | Husk , Agro Waste |

| Capacity | 1 TPH to 15 TPH (F&A 100OC) |

| Pressure | 10.54 Kg/Cm2 (g) to 21 Kg/Cm2 (g) |

Preferred Buyer From

| Location | Anywhere in India |

The SUPER PAC Boiler with its high performance and automatic modern styling confirms to the most exacting standards of safety, performance and efficiency. This boiler is manufactured with the latest engineering techniques, modern production equipment and with the expertise engineers and workers. The benefits include fuel flexibility, high efficiency, low emissions and reduced capital and operating expenses.

The filling of the boiler is done through a feed pipe connection. This water flows through the water wall membrane. It circulates the water from the water wall membrane to pressurized part of the boiler. As firing is done it raises the temperature of water wall membrane, it goes through perforated pipe and mixes with water which is present in pressurized part of the boiler. The smoke is emitted from flames and flow through the smoke tubes. The pressure part is full of water. When the temperature of smoke tubes raises, there is the formation of steam in the top space of the boiler. Steam is collected through the steam outlet. Man Hole is given for cleaning purpose.

Features :

- Offer improved efficiency and operating flexibility in the most economical manner

- Substantial Savings on fuel costs

- Fludized Bed Coumbustion with Multi-fuel firing

- Optimum combustion with appropriate secondary air system

- Machine-welded membrane panel

- Membrane panels provide gas tight enclosure for better efficiency of boiler & minimum refractory

- Inbed & Economizer Evaporator design for better reliability and temperature control

- Dependable quality of components like valves, pumps, safeties & instruments

- Easy access for cleaning and inspection

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBPL |

| Working Temperature | 70-100 Degree C |

| Usage | Industrial |

| Finishing | Unpolished |

| Fuel | Coal, Husk, Petcoke, Agro Waste, Bagasse, Wood Logs / Wood Chips, Saw Dust, Biomass Fuels, Ground Nut Shell, Spent Wash, Cotton Stock, Palm Fiber |

| Capacity | 10 TPH to 40 TPH |

| Pressure | 10.54 Kg/Cm2 (g) to 65 Kg/Cm2 (g) |

Preferred Buyer From

| Location | Anywhere in India |

Water Tube Boilers has unique design with ample water holding capacity, tall furnace for complete combustion of fuel particles within the furnace zone. High Pressure Boilers with highly advance technology enables the most efficient combustion of fuel as well as makes the boiler highly fuel flexible. Water circulation through the boiler is also either natural circulation because density distinction or by forced circulation.

High Pressure Boilers has wide applications in wide range of industries like paper, textiles, chemicals, distilleries, rubber solvent, pharmaceuticals, food processing etc. High Pressure Boilers operates with different type of furnaces like, FBC, traveling grate, pulsating grate, dumping grate etc.

Features :

- High Thermal efficiency

- Fluidized bed combustion, Travelling Grate & Dumping Grate for high ash/low grade fuels as per fuel requirement

- Membrane panel construction for fuels with low ash fusion temperatures

- Clean boiler house environment through enclosed and mechanized fuel feeding and ash retrieval system

- Automatic fuel feed control to ensure steady the steam flow

- Easy of maintenance : Total accessibility to pressure parts and furnace from both inside and outside

- Quick and easy start ups and relighting made easy

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | CBPL |

| Material | IBR Grade Plate |

| Application | Steam Producer |

| Shelf Life | 15 Year |

| Technique | Double Pass |

| Warranty | 1 Year |

| Delivery Time | 45 Days |

Preferred Buyer From

| Location | Anywhere in India |

An excellent manufacturer in Wood Fired Boiler. Starting from 1 TPH to a Max of 20 TPH in Water Cum Smoke Tube Model.

Installing all IBR recommended parts with complete installation// Standard scope as per the requirement.

Delivery with in 45 Days.